A cable bus is an electrical power distribution system in high rise buildings as well as the power generation, mining, petrochemical, paper, heavy industrial and commercial industries.

It is made up of insulated conductors that have been mounted in a ventilated metal housing designed with cable support blocks. The cable support blocks installed in the metal housing help to maintain cable spacing and prevent short-circuiting.

This power distribution or cable bus system, also includes all necessary equipment connections, wall entrance seals, cables, flanges, elbows, fire stops, assembly hardware, offsets, and termination lugs and kits.

How Does Cable Bus Work?

Typical applications of a cable bus system range from 1000 to 5000 Amps/600V, 5kV, and 15 kV. The cable configuration is designed to balance the current in each individual conductor and allow the cables to operate at their highest efficiency, where losses and imbalances between individual conductors are minimized.

Why choose superior Cable Bus?

View Our Modular Cable Bus Power Distribution System Products

Cable Bus systems are fully engineered with emphasis placed on power cables, phasing arrangement and system balance, short circuit capacity, and grounding requirements. Each one of these design considerations must be analyzed separately to determine how it affects the design of the overall electrical power system.

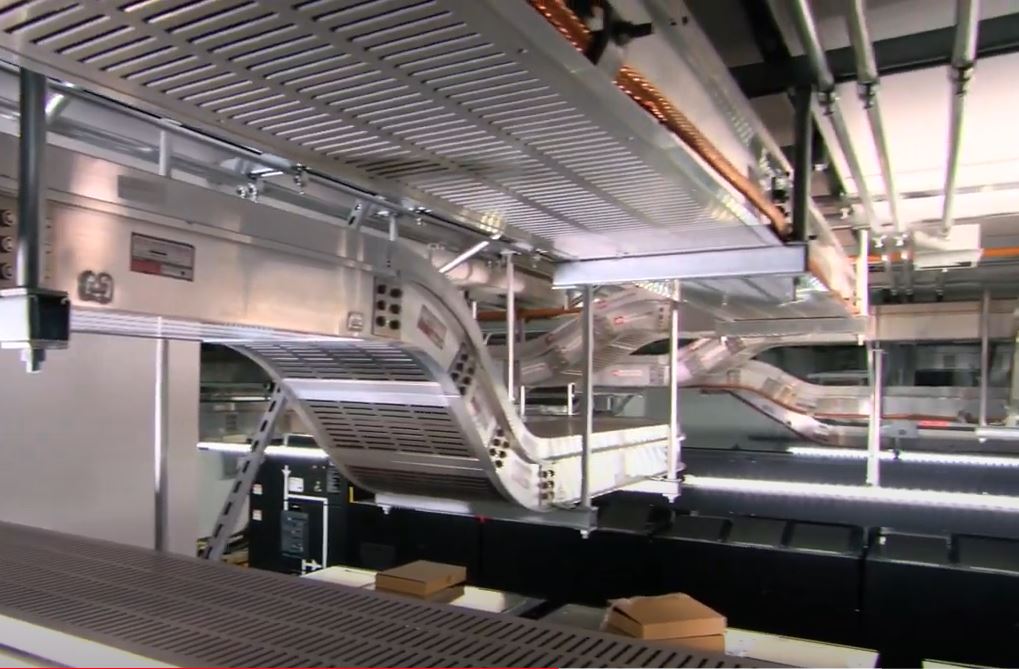

Cable bus is used for a wide variation of busway lengths from relatively short feeders that are about 10 to 30 feet to electrical feeders that are several thousand feet in length. High-quality continuous conductors are designed in an engineered phasing arrangement and spacing to achieve superior performance.

In this article, we discuss Superior Cable Bus in detail.

This allows for a minimized impedance and voltage drop, an optimal balance of loads between the conductors, and maximum load-carrying capacity because of free air rated conductors. A good cable bus system utilizes special cable support blocks that provide quality cable bracing to withstand large momentary short circuit. These cables are mounted parallel to each other throughout the entire bus housing without interweaving.

In this article, we review What is HV and LV Power Distribution Systems.

Precautions to Take When Installing Cable Bus

Since potential accidents can cause significant damage, it is important to provide additional protection measures as voltage level increases. It is crucial to observe electrical safety in any cable bus indoor or outdoor installations as it helps to reduce your operation and maintenance costs. The best advice is to work with professional electrical design engineers to ensure your cable bus system installation meets the national electrical codes as well as local standards.

Short Circuit Capacity

Short circuit currents cause mechanical stresses that Cable Bus must be able to tolerate. The conductors’ forces are transferred to the cable supports. Cable Support Blocks, Braces, and the enclosure are all support elements of a Cable Bus system.

A symmetrical AC component and a fast dropping DC component make up a short circuit current. The mechanical strength of Cable Bus is designed to handle the greatest instantaneous current as well as symmetrical currents that may last several cycles. The actual value that the circuit breaker will interrupt is the symmetrical current.

Because Cable Bus systems are frequently used for major feeder connections (e.g., substation or generator to switchgear, load centers, and high voltage machines), the available short circuit current is the utility or generator supply via the transformers. The Cable Bus may feed huge motors in some circumstances, and the motor’s contribution to potential short circuit pressures must be taken into account. There are plenty of tables available that detail motor contributions under various operating situations.

Cable Bus Advantages

Cable Bus Systems Are Easy to Install

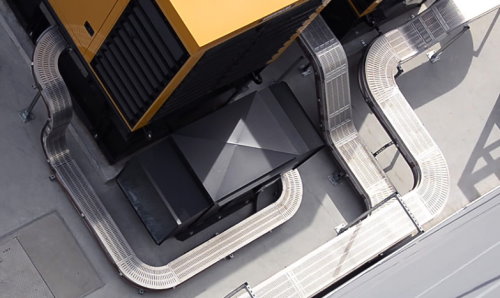

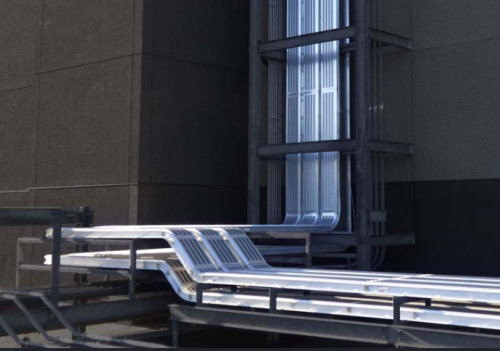

Cable bus is easy to install compared to other electrical systems, as it does not require special tools or heavy lifting. Housing sections can be easily fitted to their designated spaces reducing the amount of time and labor spent on installation. Whether used in indoor or outdoor installations, every project is designed and engineered to fit the particular application with all cable bus sections to fit your project needs. Short circuit braces allow easy installation of long vertical sections since interleaving or crossing of conductors is not required.

Requiring only two workers for installation, instructions are straight forward and are accompanied by blueprints and an easy to read guide. The installation is easy because of information provided for a solution that’s already been walked, engineered and designed between the construction team in the field and the cable bus design team.

Whether you are on a pre-cut installation or a cut to fit installation that has many different aspects to it, cable bus can be engineered to fit with solutions and products for the different entrances and exits out of equipment and buildings, both indoor and outdoor.

Superior Reliability

Cable bus systems that feature high-quality cables are reliable and eliminate faulty splices because they are continuous from one terminal to another. They utilize fully insulated conductors that are manufactured and designed to withstand the outdoor environmental factors such as moisture or sunlight. The metal casing is ventilated aluminum for both indoor and outdoor applications and does not require filter breathers, or heater strips to keep moisture out of the cable bus.

Cable Bus also eliminates all intermediate insulation splices in addition to conductor splices. From source to load, the cable insulation material, like the conductor, is continuous and homogeneous.

Because connections account for over 90% of all electrical failures, reducing conductor connections and insulation splices improves system reliability significantly!

Cable Bus is made of corrosion-resistant aluminum and use stainless steel fasteners to extend the system’s service life. The cables utilized can be used both indoors and outdoors. Without the use of expensive equipment, two individuals can easily hoist a Cable Bus cage into place.

Affordable Pricing Regarding Installation, Maintenance and Operation

Cable bus advantages extend to the overall and upfront cost. They are significantly lower cost installations than conduit or non-segregated bus duct and wire systems in most electrical applications that exceed 1000 Amperes.

Cable Bus can save up to 30% on material costs when compared to equivalent 5KV and 15KV Bus Duct Systems due to it’s innovative design and it’s ability to streamline production. Cable Bus systems are also cost-effective when compared to 600 Volt Bus Duct systems.

To optimize cost savings of a cable bus provides even greater savings over other systems as the cost of copper or ampacity increases. There are no power losses from intermediate connections or splices in a cable bus since it is continuous. Since its conductors are properly space, phased, and secured, it has a lower voltage drop and a lower impedance that provide long-term energy savings along with being cost effective initially.

For the total installed cost of the system, the significant difference in material costs supports Cable Bus. Not to mention any potential startup delays due to installation concerns caused by a lack of flexibility if the Bus Duct system does not properly align due to field fluctuation and Bus Duct’s lack of adjustability.

Designed to Suit Your Specific Needs

Enclosures are available up to NEMA 4X and designed to suit system specific requirements. They can be bolted directly to transformer or switchgear equipment and allow for easy terminations.

Custom fittings are the perfect answer to routing in tight areas. Non-standard radius and angle fittings are available to suit your job site, no matter how it’s configured.

Flexible and Versatile

A good cable bus electrical system is designed to accommodate unexpected differences between the actual construction and engineered drawings with little or no delay. Additional cables and housing are provided to accommodate equipment that may be misplaced in the field. One of the greatest cable bus advantages over other power distribution systems is that it can be easily cut or adjusted in the field if the equipment placement requires a shorter bus length.

Unexpected dimensional changes during installation are significantly more forgivable with cable bus systems. Cable Bus enclosures can be cut shorter in the field, just like Cable Trays, if necessary.

In most circumstances, Cable Bus can accept a 12-inch or greater increase in the length of the bus system. For terminations, a specified amount of backup cable is usually provided. If the system length needs to be increased somewhat, there is usually one or two feet of extra cable available.

Furthermore, unlike Bus Bar systems, Cable Bus does not require precise alignment with existing bus bars in transformer or switchgear compartments.

In actuality, due to the flexibility of the cable and the contingency cable length normally supplied for terminations, Cable Bus has a somewhat big envelope for entrance into equipment.

The cable bus has the added benefit of being the only type of installation where the manufacturer’s design ensures that the conductor current is as balanced as possible. Another advantage of cable bus is its routing and design flexibility, which is similar to cable trays in that we ship bottom sections and manufacture our own elbows, allowing us to go at any odd angle required. If necessary, cable bus can still use hinged splice plates. Extra cables and spare enclosure pieces should be included to cater for any slight changes in the field.

cable bus requires extremely little maintenance

A cable bus system is easy to maintain unlike non-segregated phase bus duct systems that do not have space heaters, splices, and connections to re-torque. They are supplied in corrosion-resistant aluminum housing and may utilize stainless steel hardware to extend the service life of the system. A good cable bus system can last for a very long time without any problems because of its quality construction materials and ability to withstand large momentary short circuit.

During a plant inspection, the connections should be inspected. It’s also a good idea to use a thermal image camera to check for hot spots on these connections.

Cable bus systems are designed to operate in the harshest environment. It does not require heater strips or thermostats since the enclosure is well ventilated, thus results in fewer failures. The use of a reliable wire management system allows for a simpler and safer installation. A cable bus system can be very useful in delivering electric current to power outlets, lighting fixtures, and HVAC equipment in your building or business.

Interested in a Customized Cable Bus Power Distribution System for Your Project?

Call 253-579-4473 or Contact Us for a Quote.