Some places, like factories and warehouses, have moving machines and appliances configured so that the workstations keep shifting. A good example is a factory where machines are moving along an assembly line. If the electricity support and source remained stationary, this would create a chaotic scene since cables would be dangling all over the place. This is where the busbar comes in. Busbar is used to ground and conduct electricity in an orderly, more flexible, and less expensive manner. This article gives more information on bus bars, or as they are commonly known, busbars.

Learn More About Our Company:

ABOUT US | OUR PRODUCTS | CONTACT US

Appearance and Nature

Also known as busses, busbars are mainly made of metals that are good conductors of heat including copper, brass, and aluminum. Because of its great properties in electrical conductivity, copper is the most preferred metal when making busbars because of all the metals that are good at conducting heat, copper offers the best ampacity. It is also lighter, which allows the busbar to be suspended overhead working stations in industrial plants. Copper also offers high resistance, resulting in minimal energy losses where the busbar is applied.

Copper can also withstand years of service with minimal wear and tear, which makes it very economically sustainable. Its resilience to higher temperatures makes it safe for use in the case of short circuits.

Application of Busbars

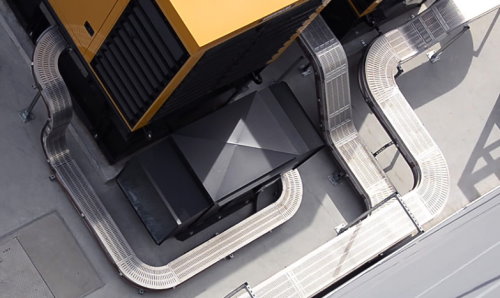

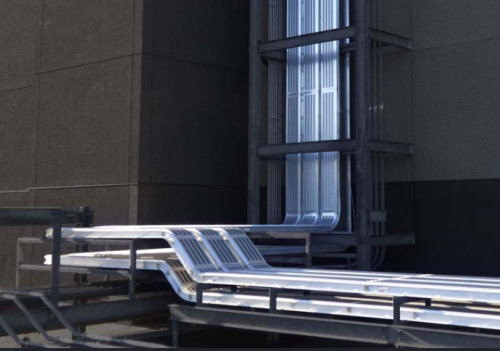

Busbars are widely used in large installations to distribute three-phase electricity in places where it would have been impossible to do so with other forms of distribution. Similar to Cable Bus, some of the places you will find busbars include hospitals, data centers, factories, universities, and laboratories. They help distribute electrical energy in places where chaotic scenes of tangled wires and cables would affect a smooth workflow. This comes with a sense of professionalism that works by improving the image of your company amongst your clientele.

Advantages of Busbars

Installing busbars in your facility comes with loads of benefits that will make your money worth the investment. The main benefit to reap from busbars is that they are cost-effective in many aspects. For example, you do not need to reconfigure the system when connecting and disconnecting the plug, which leads to less or no maintenance costs at all. With busbars, you do not need to dig through the facility to find electrical channels; all you have to do is suspend the bus and get the connections up and running. This eliminates the need to hire electrical specialists, thereby saving your company lots of money and time. The fact that the busbar eliminates extra construction works means well for the environment since fewer or no waste is produced from the project.

Types of Busbars

Busbars come in a wide range of sizes, which are dependent on the need where they are being applied. Some of the common busbar sizes for commercial and industrial uses include 40, 50, 60, 100, 225, 250, 400, 800, and 1200 amps. The u-shaped busbars are the most common type. This is because of the many advantages that come with this type of busbar. Fabricating the busbar into a U shape is meant to prevent the bus from collapsing due to too much weight resulting from the excessive force. The shape allows for more pressure at every plugin joint, something that ensures little or no maintenance at all. This is very sustainable for small and medium enterprises. U shape also allows for multiple plugin units something that makes electrical distribution blissful. The multiple plugin units on a u-shaped busbar enable relocation, simple expansion, and reconfiguration.

Checking arrangements utilized in busbar frameworks gives consistent information from a short review down to the individual source level. Force use information can be received locally or distantly permitting you to settle on deliberate energy productive choices. Observing arrangements utilized in busbar frameworks gives consistent information from a concise diagram down to the individual source level. Force utilization information can be gotten to locally or distantly permitting you to make deliberate energy productive decisions.

Power checking assists with distinguishing load lopsidedness before it affects your hardware’s presentation. Constant checking permits you to catch changes because of new hardware and address a possible issue before vacation happens. Monitoring power utilization empowers your organization to scale with precision. Some busbars offer force monitoring. This observing arrangement can be utilized as an independent framework mounted to electrical boards, or can likewise be fused into busway end feeds and branch-circuit applications to quantify the measure of intensity being drawn.

Interested in a Customized Cable Bus Power Distribution System for Your Project?

Call 253-579-4473 or Contact Us for a Quote.

Frequently Asked Questions

Q: How are electrical bus or electrical buss fuses used?

A: An electrical bus bar is a collection of wires, typically in a single sheath, that allows electricity to be distributed between devices. A buss fuse is a fuse that is placed on an electrical buss bar in order to protect the devices connected to that bus from damage in the event of an overload or short circuit.

The primary purpose of a bus fuse is to protect the wiring and connectors on the bus from being overloaded and causing a fire. In addition, by isolating the faulted device from the rest of the circuit, a bus fuse can prevent damage to other devices in the circuit.

Additional Resources

- What is Relay and Busbar?

- What is Cable Bus? Superior Cable Bus Explained.

- What are Some Examples of a Bus in Electronics?

- Why is Busbar Preferred Over Cable?