The Benefits of a Properly Installed Cable Tray System

When a cable tray wiring system is properly installed, it provides great dependability in any situation, offers the safety of the electrical system, and saves space, labor, and materials. The maintenance of a properly installed system is also better than that of any other system.

Factors to Consider When Installing a Cable Tray System

Before installing a cable tray system, you need to consider a variety of factors to ensure everything works according to plan.

- Inspection

The first thing you need to do is inspect all trays and accessories that you receive on-site. The equipment should be handled and stored according to the Project Procedure for Material Control. An electrical contractor or QC inspector should do this task to ensure everything received is of the right standard. For instance, the cable tray protection covers and trays should be manufactured from hot-dip carbon steel. In addition, the installation should be self-supporting with a wide flange based in accordance with the cable cross-section.

- Installation Factors

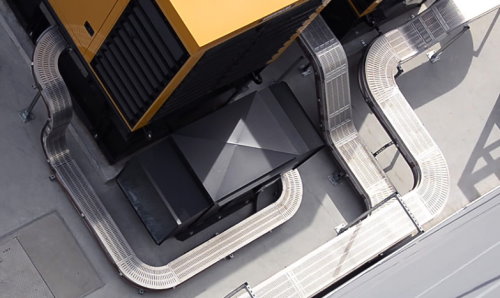

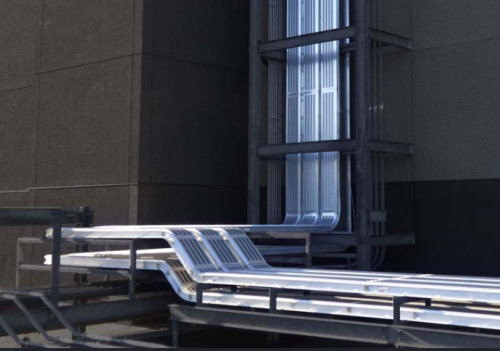

Cable tray installation can be conducted in a flat building or operating structure. The tray runs under the flooring or walkways. However, the tray can be installed vertically or around an edge, but this happens in special situations. On a horizontal cable tray system, flat insulated electrical cables are laid and fixed in a group, and on a vertical cable tray system, horizontal cable trays are laid and fixed with 20mm stainless steel strips.

A cable tray system should be fixed onto standard steel shapes and fixed onto a concrete structure with self-drilling dowels. The distance between the cable tray support spacing and fixing points should be a maximum of three meters. The system should also be designed to support a maximum load of 100kg/m.

Another point to consider is a cover fabrication because covers should be provided in instances where there is a risk of mechanical damage during installation or maintenance periods. The fabrication process should be similar to that of a cable tray system and fixed with the right clips in accordance with Manufacturer and Vendor requirements. Read this article to learn Is Tray Cable Plenum Rated?

Cable Tray Installation Process

As earlier mentioned, the cable tray system should be installed based on the specifications and requirements given by the manufacturer.

The first step in the installation process is to locate the area to install the cable tray system. This should be done according to the Issued For Construction (IFC) drawings. The next thing is to prepare all materials and tools needed for the installation work. Tools should also be tested during this time to ensure they are working optimally.

Afterward, install the cable tray support to ensure the stability of the cable tray system. As you do this, ensure you have enough space to allow for adequate access for installing and maintaining the cable tray. Cable tray fittings, sections, and raceways should be connected using bonding jumpers or mechanical connectors.

What is the Testing Procedure for a Cable Tray System?

To ensure the cable tray system is in optimal operation, you have to do a few checks to ensure everything is in the right place. You have to confirm materials and make sure they are according to Issued For Construction (IFC) drawings, do visual inspections to see the cable tray rung space, height, length, and width, check supports and braces to make sure they can handle the weight of the cable and tray. You also need to check that the cable tray installation does not interfere with other equipment or services and that connectors and joints are well installed. To ensure the cable tray system is sturdy enough, you have to hold down clamps and anchor them on needed places and ensure bolts, nuts, and the structural system is securely fixed.

A cable tray system is an assembly of sections or units that form the structural system used to support installed cables and raceways. As an owner of a building, you do not need to know about how the installation work is done because you have experts to do the work for you. However, as an electrical or mechanical engineer, you have to know to ensure you do the installation accordingly.