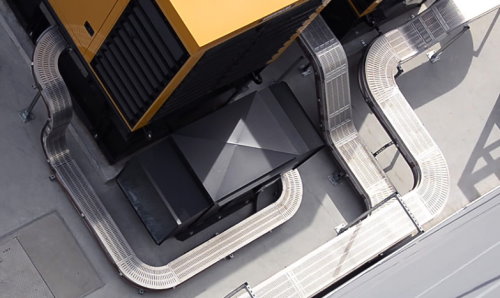

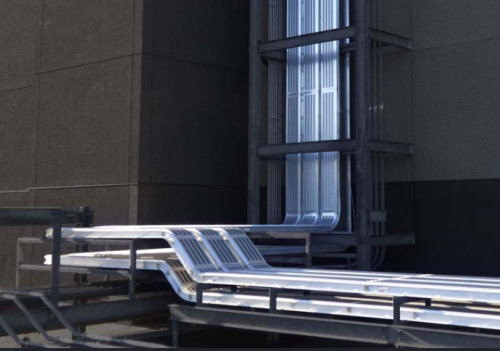

A cable tray is used in the electrical wiring of buildings to support insulated cables, which are mainly used for power distribution. Cable trays offer a great alternative to electrical conduit or open wiring systems and are usually used for cable management in commercial and industrial buildings. They are an integral part of the design and are a major component of the equipment involved when changes to the wiring system are required.

Learn More About Our Company:

ABOUT US | OUR PRODUCTS | CONTACT US

Cable trays come in different types that fit distinct needs. This article gives information regarding these types and their uses.

Ladder Cable Tray

This type of cable tray has two side rails, which are connected by rungs. It is quite effective since ladder rungs provide you with easy accessibility to the cables. The rungs also offer a good anchor for tying down cables in cable tray runs that are not horizontal or where cable positions have to be properly maintained in the horizontal tray runs.

Solid-Bottom Cable Tray

This cable tray is preferred in instances where drooping of cables have the potential to affect overall system performance. Also, when electromagnetic interference protection is a major concern, this becomes a relevant reason for choosing solid-bottom cable trays.

Wire Mesh Cable Tray

Also referred to as a basket cable tray, this tray is made from welding stainless steel wires together to form sort of a basket-like mesh. These trays are mainly used for telecommunication, low voltage, and fiber optic cables.

Trough Cable Tray

These trays are moderately ventilated and have cable support. They come in metallic and non-metallic types and are available in all manner of standard widths. These trays are used for moderate heat-generating activities with a short to medium support span of 0.3, 3, and 6 meters.

Channel Cable Tray

These trays are used for installations with a limited number of trays. They are used in those installations where cables come out via ventilation openings and the cable channel is subject to some levels of vibration. The supports are between 1.5 and 3 meters. Channel cable trays are installed in standard widths of 3, 4, and 6 inches in metal systems and about 8 inches in nonmetallic systems. The standard length for installing channel cable trays is 10, 12, 20 and 24 feet.

Perforated Cable Tray

This cable tray has a ventilated bottom that contains side rails. It offers a lot of support to cables compared to the ladder cable tray.

Single Rail Cable Tray

A single rail cable tray can have both single and multiple trays and they can be wall fixed or central supported. This means that these trays are quite flexible for use in power distribution. They are mostly used for low power cables.

Types of Cable Trays Based on Material

Apart from the design, cable trays can also be categorized based on the material. There are usually metallic and non-metallic cable trays in the market. Metallic trays can include those made of aluminum, steel, and stainless steel. Non-metallic trays can be made of out a material like fiberglass. This part of the article looks at these different cable trays in detail.

Aluminum Cable Trays

Aluminum cable trays can be used in almost any kind of environment. These trays are widely known for having a commendable resistance to corrosion and great strength-to-weight ratio. In addition, aluminum trays are lightweight, meaning they are quite easy to work with.

Steel Cable Trays

Steel cable trays are strong and quite inexpensive. They are commonly used for low thermal expansion and electric shielding. They only disadvantage is that they are lesser corrosion resistant and quite bulky, making them a bit hard to work with.

Stainless Steel Cable Trays

These cable trays are highly resistant to dyestuffs and offer great resistance to organic and inorganic chemicals in very high temperatures.

Fiberglass Cable Trays

Fiberglass trays are non-conductive and offer great resistance to corrosion. They are also lightweight, meaning they are easy to work with. However, installers have to ensure that the bend radius for the coaxial or fiber-optic cable is properly maintained according to standards.

A cable tray can be referred to as the bridge that allows safe transport of wires through open spans and offers protection to the cables against overheating. This cable management system comes in different types that fit distinct uses. This article has explained different cable trays such as ladder, perforated, galvanized, and PVC. This information assists you in selecting the best cable tray for your project depending on your specific needs.

Still have questions? Call us at 253-579-4473 or Contact Us to talk about

the best products and design for your project.

Additional Resources

- What is HV and LV Power Distribution System?

- How Does Cable Tray Installation Work?

- What are Some Examples of a Bus in Electronics?

- What are Relay and Busbar?

- How Much Voltage Drop Can a Busbar Withstand?