Tray cables are a type of multi-conductor cables used in industrial environments and suited for both power and signal transmission. The cables are usually installed via conduits, ducts, wire trays, and even direct burial usage.

Tray cables are installed in buildings and should be plenum rated, which means they comply with smoke and flammability specifications put together by the National Electrical Code (NEC). This article gives information regarding the importance of using tray cables that are plenum rated.

What is a Plenum Rated Tray Cable?

A plenum-rated cable is fitted with special insulation, which has low smoke and flame characteristics. This kind of cable should be installed in an air-handling space. For instance, large buildings use the ceiling to return air to the AC unit. Therefore, the ceiling can be referred to as a plenum ceiling because all cables that go through it have to be plenum rated. Plenum-rated cables come at a higher price because they must meet the required standards.

When cable is being installed in a building, installers have to consider plenum spaces, which are the open spaces below the floor or above the ceiling. They are used for air circulation but they can be problematic in case of a fire due to the high levels of oxygen and lack of fire barriers. The use of untreated cables in plenum spaces can spread fire quite fast, making it crucial to use plenum cables.

Plenum cables come coated with a flame retardant and are usually made using plastics, which do not smoke like other plastics. This is done to prevent the issue of spreading fire. Therefore, any cable installed in plenum spaces should be plenum rated.

We go into detail about What is Relay and Busbar in this article.

Benefits of Using Plenum Rated Tray Cables

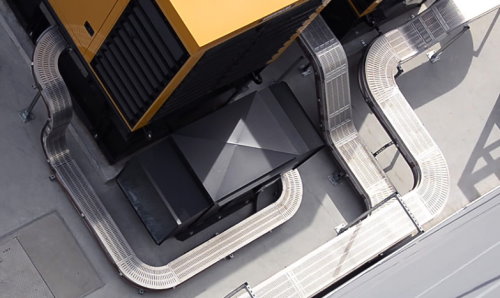

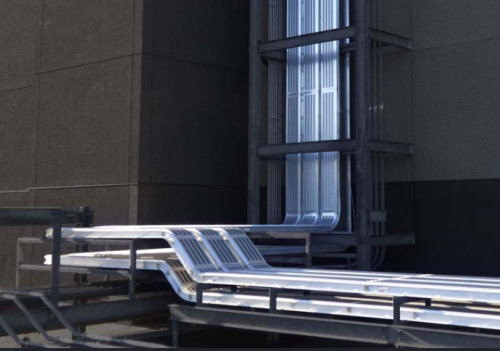

A cable tray system helps support, protect, and route cables as part of the cable management system. It supports insulated electrical cables mainly used for power distribution. Plenum-rated cables are good products and are able to withstand severe environments. They come with plastic or metal protection over individual conductor insulations. These cables can be plenum rated for the indoors, outdoors, hazardous locations, corrosive areas, or high electrical noise areas.

To indicate that they have been tested for ratings, these cables need to be UL listed. This should confirm they have been tested for ratings that entail mechanical resistance, flammability resistance, and temperature limitations. Most plenum rated cables must have a crush and impact test before listing and are rated as exposure rated (ER).

If you have seen normal plastic burn, then you understand why cables need to be plenum rated. Normal plastics burn quite fast and they let off plumes of a dirty, toxic, and block smoke. These normal cables are usually unrated and should never be used in constructions. The reasoning behind this is that if they catch fire, they can spread it to other parts quite easily. By working with plenum rated cables, you can be sure that they are of high quality and will not spread or cause fires. You can read about Cable Bus Sizing here.

Building Codes and Plenum Rated Cables

Building codes have evolved over time to ensure buildings are as safe as possible for their occupants. These regulations touch on everything including water, electricity, and gas. In regards to electrical cabling, a building has to use high quality cables to comply with local building laws. For instance, cables have to follow color codes where live wires are either brown or red and neutral wires black or blue. This plan enables repair work to be done safely since wire identification will be quite easy. Wires also need to be of a certain size to ensure they are able to carry the needed current. Small wires can overheat very fast and become a risk.

Drawbacks of Using Plenum Rated Tray Cables

Although plenum-rated tray cables are quite beneficial, they do have a few drawbacks. A major disadvantage is that they are quite expensive. This is because they come with a special design, a major reason why most contractors use plenum tray cables in plenum spaces. Another thing is that they are usually stiffer than normal cables because of their fire-retardant coatings. This means they are more prone to insulation tearing.

If you are a contractor or builder, you are tasked with choosing quality tray cables for the building project you are undertaking. Your client might not understand about cable quality so you need to do a good job for them. Choosing to go with plenum rated tray cables is a great idea because they have been proven to withstand severe conditions that affect a power distribution system.