A good cable bus system uses parallel conductors that have been braced in a rigid enclosure to distribute very high current and voltage between the power source and load center. The installation phase of a cable bus system is very essential as it determines the overall efficiency and effectiveness of the entire system. Insulation conductors should be fully continuous from the source to the load. Improper installation of the cable bus system is the root cause of power cable failures and can cost you a significant amount of money on necessary repairs or replacements. This article looks at some factors you should consider before installing a cable bus system.

Shielding

Shielding is used to confine the conductor’s dielectric field to the cable insulation. Metallic shielding must be grounded solidly when installing a shielded cable. It is important to study the installation ahead of time to determine the best grounding method. Shielded power cables are often used for applications above 2500 volts or where there is a concern for personnel safety. They can also be used where cables may be subject to soot or other heavy deposits forming paths to the ground. The above load conditions and length of the circuit determine the required shielding methods for any particular reason.

View Our Modular Cable Bus Power Distribution System Products

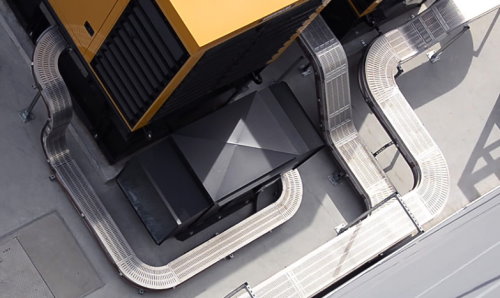

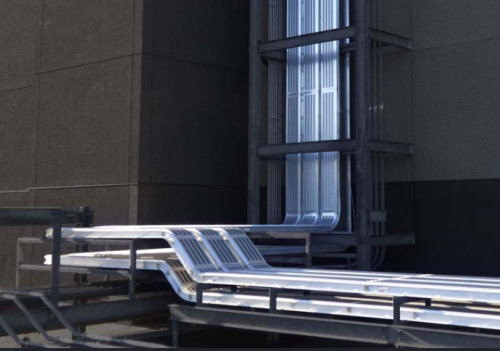

Flexibility

A cable bus system needs to be flexible and adaptable to any unexpected circumstances that are likely to occur during construction. Each size and rating of a cable bus system is supplied with a spare length of the housing and 5 percent extra cable including the cover, hardware, and cable support blocks. This makes it easier for the installer to adjust your cable bus system to correct any differences or discrepancies between the actual field construction and engineered drawings. A system with a compact design and radius bends allows easier maneuverability during installation as they can fit in tight clearance applications.

Short Circuit Capacity

A cable bus system installation should take into account dangerous mechanical forces that may be created by short circuit currents. It should be able to withstand these forces, which are often transmitted from the conductors to cable supports. Short circuit currents are comprised of a rapidly decreasing DC component and a symmetrical AC component. The symmetrical current refers to the actual value that can be interrupted by a high voltage breaker. When selecting a cable bus system, it is important to ensure that its mechanical strength stands up to the maximum instantaneous current as well as the resultant symmetrical current.

Grounding

A good cable bus system should guarantee the safety of people and property against faults that may be caused by electrical disturbances. Failures in the system-connected equipment, lightning, or electrical system failures are possible fault hazard locations that need to be taken into account during installation. All neutral conductors and metal enclosures of the system should be reduced to a common potential including the gas piping, water, steam, and structural steel of the building. Grounding provides a primary solution to all possible fault hazard locations as it connects the distribution system to the earth using a grounded or neutral conductor. It serves to limit the voltage that may occur in the circuit due to accidental contact or lightning.

System Balance

Parallel conductor-transmission lines with spaced conductors have been used for many years. However, the electrical coupling can cause an imbalance in currents between the conductors of a parallel conductor system. The conductor currents can be balanced using an overhead transmission line transposition of conductors that are widely spaced. The recommended spacing of conductors in a cable bus system is one cable diameter or one to three inches. Relatively short lengths and close spacing can make the transposition of conductors a practical impossibility for balancing purposes.

Constant Reliability

Splices create a point of failure in any electrical system. A good cable bus system should be installed with continuously insulated power cables that transmit large electrical current from the source to the load center without any splices. This can dramatically improve the system’s uptime and contributes to the long service life of the system. There should be no power losses from intermediate connections or splices with a continuous cable bus system.

After installation, it is important to inspect your cable bus system regularly to ensure everything is operating efficiently and at optimum capacity. Identifying the root cause of cable failures at an earlier stage ensures a reliable operation in the future, as it leads to better maintenance practices. It is important to consider all the above factors before installing a cable bus system to improve the flexibility of operations and prevent future failures.

Interested in a Customized Cable Bus Power Distribution System for Your Project?

Call 253-579-4473 or Contact Us for a Quote.

Additional Resources

- What is the Difference Between a Busbar and a Feeder

- What is Cable Bus? Superior Cable Bus Explained

- What are the Basics of Electric Power Distribution System?