A reverse power relay is a protective transmitter that protects the turbine or motor from damage upon a reverse power condition. A generator can work as a synchronous compensator if the driving torque is less than the total losses in the system, taking necessary power from the network.

For instance, reducing the steam flow in steam turbines can result in overheating since the cooling effect of the turbine blades is reduced.

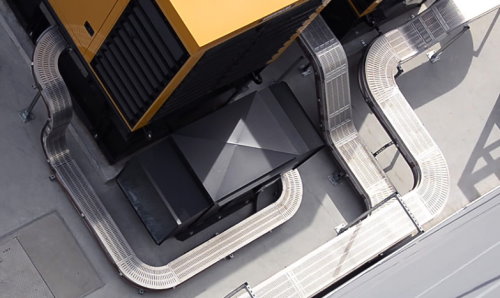

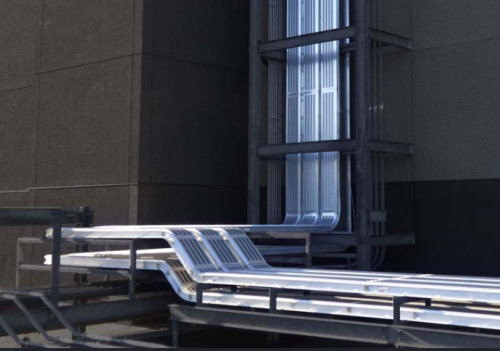

View Our Modular Cable Bus Power Distribution System Products

The initial stage of a reverse power relay is to prevent excessive over speeding if the steam-powered generators are taken off service. The second stage prevents overheating and possible mechanical damage to the prime mover. This article discusses everything you need to know about the reverse power relay including how it works and why it is required.

The Components of a Reverse Power Relay

A relay is made up of a light, non-magnetic aluminum disc that is sandwiched between two laminated iron core electromagnets. A Voltage Coil (PT) wounds the upper magnet that is supplied from a single-phase and an artificial neutral of the generator output. The Current Coil (CT) wounds the other output magnet that is connected to the same phase as the voltage coil wounding the upper electromagnet.

How Does it Work?

The voltage coil has a more inductive valve and induced current because it has the highest number of turns. The induced current of the voltage coil lags by an angle of 90 degrees. On the other hand, the current coil has a less inductive valve and induced current because it has the lowest number of turns. It is because of this reason why the current coil lags less than the voltage coil. A conductor that carries the current produces a magnetic field, which means both upper and lower electromagnets produce magnetic fields.

However, the induced current in the voltage coil lags more in voltage coils than current coils. This means that the magnetic field produced in the lower section will be higher than the upper section and there will be a difference of 90 degrees between both magnetic fields. Both fields produce eddy currents when they pass through the aluminum disc. Eddy current refers to induced loops of electrical current within conductors by altering the magnetic field in the conductor.

Torque is generated because of the formation of eddy current causing the disc to rotate. The trip contact on the disc remains open under normal power flow and the stoppers restrict rotation. However, the disc rotates in the opposite direction if a reverse power starts to flow, moving it away from the stoppers in the direction where the trip contact was activated.

When Does the Reverse Power Flow?

The reverse power can flow because of a loss of excitation in the alternator or faulty governor of the prime mover. The generator may start behaving like a motor if the prime mover is not supplying enough torque to keep the rotor spinning at the same frequency as the connecting bus. The generator will draw power from the bus bar rather than supplying power causing a reverse power flow. It can also occur if the synchroscope is rotating slowly and then closing the breakup during synchronization. Instead of supplying current through the bus, the generator will be drawing current from the bus. This usually happens when the breaker is closed and the synchroscope is rotating fast in an anticlockwise direction.

Why is Reverse Power Relay Important?

When multiple power units are running in a parallel direction and reverse power flow occurs, they may switch to drawing power from the main bus bar. This can overload the power supply unit, causing a total power failure or a preferential trip. The faulty unit will continue drawing power from the main bus bar, causing a motoring effect. In the worst-case scenario, the RPM will soot up leading to over speed trip or mechanical failure to the motor or turbine. A reverse power relay prevents all these problems from happening by preventing overheating and possible mechanical damage to the prime mover. It also prevents the turbine or motor from excessive over speeding to maintain the regular cooling effect of the turbines.

A reverse power relay prevents the generator from going to a reverse direction by monitoring its power supply. It quickly activates the trip if the output falls below a preset value and disconnects the generator to avoid any damage. A boost test push button can be used to test the reverse power relay through simulation to check if it gives a trip signal.

We customize power distribution systems for your project.

Call 253-579-4473 or Contact Us for a Quote

Resources

- What is Relay and Busbar?

- What is the Difference Between a Busbar and a Feeder

- What are Some Examples of a Bus in Electronics?

- Electrical Grids: What are Bus and Busbar?

- How Much Voltage Drop Can a Busbar Withstand?